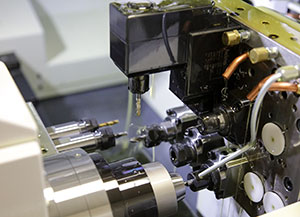

CNC Swiss Screw Machining

Capacity 0.03125”-1.250”/ 1mm-32mm

Tolerances to .0002″

Lengths to 12′

CNC Swiss machining technology offers one of the most cost-effective and accurate solutions for producing highly intricate parts, both small and long. Unlike conventional turning in which the material remains stationary and the cutting tools move to the material, CNC Swiss machining utilizes a support system, called a guide bushing, allowing the material to move under the cutting tools creating a very rigid “point of cut”.

This greatly diminishes deflection and vibration, which helps to further improve machining accuracy. In fact, our highly advanced CNC Swiss machining centers can meet ultra-tight tolerances down to 0.0002″.

Quality in Numbers

Many of our CNC Swiss machining centers are equipped with live tooling for cross drilling, tapping, and milling along with sub spindles for part pick off. This allows for simultaneous machining on both ends of a part for greater production output.

INDUSTRIES

We've got your solution:

- Defense

- Emerging Technologies

- Medical Device

- Food Production

MATERIALS

Quality starts here:

- Aluminum

- Brass

- Bronze Alloys

- Copper Alloys

- Magnesium

- Nickel Alloys

- Other/Please Inquire

- Plastics

- Stainless Steels

- Steels

- Titanium

CONTACT US

Get started:

NORTH EASTON MACHINE • 218 Elm Street • North Easton, MA 02356 • 508-238-6219